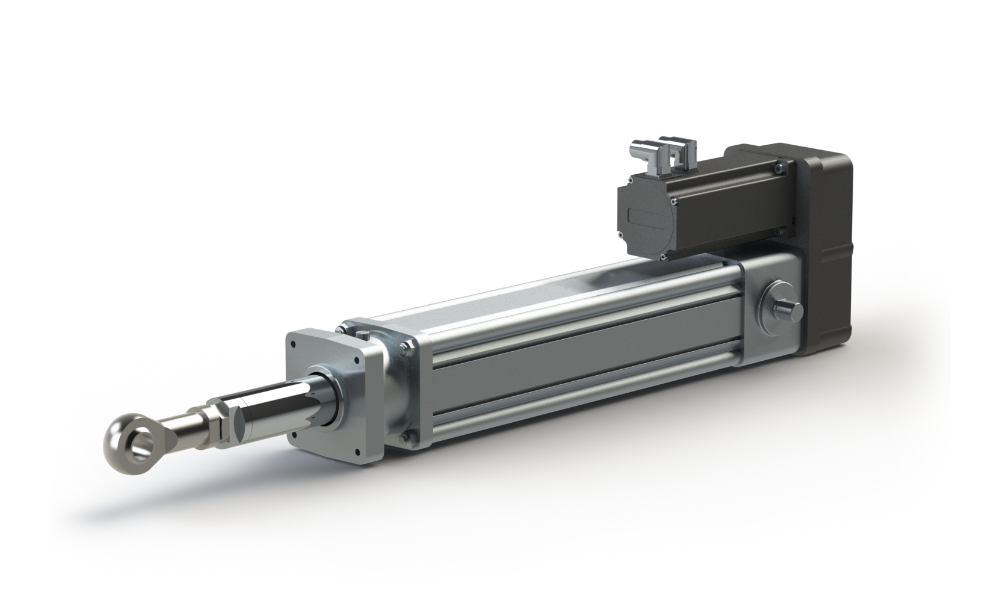

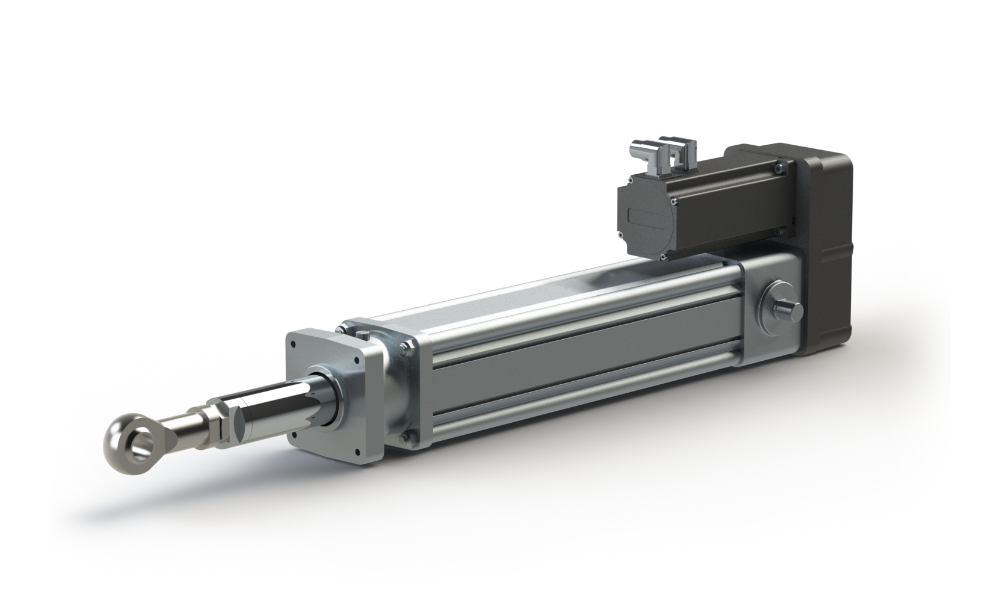

Actuator

Design tool

Orientation & Application

Load cycle

Motion profile

Actuator selection

Configuration:

Mass: i

Stroke: i

Coefficient of friction (µ): i

Tilt angle: i

0°=horizontal, 90°=vertical

Process force: i

Direction of the process force: i

Cycle time calculation

Stroke time in one direction: i

Break after each stroke: i

Number of strokes per load cycle: i

Cycle time:

Lifetime calculation

Number of load cycles per hour:

maximum number:

Operating hours per day:

Days per year:

Years:

Total number of load cycles:

Required lifetime:

No entries are required here, please check the calculated load cycle and then click Next to go to the preselection of suitable cylinders.

Trapezoid profile according to 1/3 rule

| Positioning way | m |

| Positioning time | s |

| max. Speed | m/s |

| Acceleration | m/s² |

| tb | s |

| tk | s |

| tv | s |

| t Break | s |

Select motor mounting

Actuator capacity

>=50%

Hubzylinder Auslegungstool

Configuration code: i

Ihre eingegebenen Kontaktdaten:

Company:

Name:

Mailadresse:

Ihre Projektreferenz:

Ihre Anfrage können Sie uns an office@atp-antriebstechnik.at senden

Calculation inputs

| Mass | kg |

| Stroke | mm |

| Coefficient of friction (µ) (µ) | |

| Inclination angle | ° |

| Process force | N |

| Force direction of the process force | |

| Stroking time in one direction | s |

| Pause after each stroke | s |

| Number of strokes per load cycle | |

| Number of load cycles per hour | |

| Operating hours per day | |

| Days per year | |

| Years |

Motion profile

Calculation results

| Fmax Application | N |

| required lifetime | km |

| max. lifting speed | mm/s |

Motor utilization

Please select actuator beforehand

Ausgewählter Hubzylinder

Motor utilization

| Teff (RMS) | Nm |

| Tmax | Nm |

| Rotations Ø | rpm |

| max. rpm | rpm |

matching actuators

Expertenansicht

ATP Antriebstechnik GmbH & Co KG assumes no liability for any incorrect entries. In case of an order, we check your configuration for plausibility and send you an alternative proposal if necessary.