Insight into the assembly of planetary gears at ATP

Whether in undercarriages of crawler vehicles, in lifting and pivoting systems of crane systems, as drives for conveyor technology in the steel industry or cable winches in stage technology, the fields of application of planetary gears are diverse and demanding. The extensive modular system and the modular design of these special industrial gearboxes enable the optimum gearbox configuration for every application.

Trouble-free operation with low operating and maintenance costs can only be ensured by careful gear assembly.

Look behind the scenes

The 600 m² warehouse and assembly hall with overhead travelling crane offers an ideal environment for the assembly of individual parts, up to small series. The existing assembly warehouse and the painting facility enable us to respond quickly to customer requests. Our highly qualified specialists assemble a wide variety of assemblies on a daily basis and have thus been able to acquire extensive expertise in the field of gear assembly over the past 20 years.

More than 50 steps are often required for a fully assembled unit.

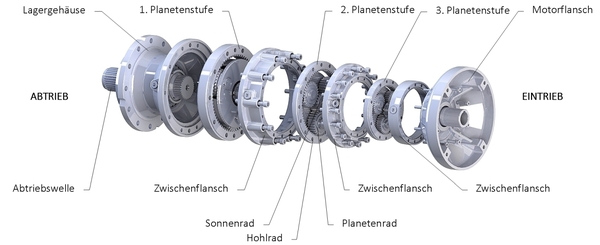

The most labor-intensive component is the gear output consisting of bearing housing, output shaft, rolling bearings and shaft sealing ring. In the first step, the output shaft with the roller bearings and the shaft sealing ring is installed in the bearing housing. Thereafter, the O-ring is used for sealing the housing and cylinder clamping pins for connection to the first planetary stage. Next, the preassembled planetary stage is placed on the bearing housing and a further O-ring is inserted. Thereafter, the planetary stage is screwed to the bearing housing and the intermediate flange.

The hexagon socket screws used are tightened exactly to the specified torque by means of a torque wrench. These work steps are repeated for the extension of the further planetary stages. In the last step, the drive consisting of input shaft, bearing and motor flange is mounted. In order to prevent oil leakage during operation, a special sensitivity is required when installing the shaft sealing rings and inserting the O-rings on the ring gears of the planetary stages.

Each gear is subjected to an extensive leak test and a final quality check before delivery. On request, individual paintings and markings are carried out in our own paint facility. This ensures quick assembly and safe commissioning.

The planetary gearboxes are supplied on request as complete drive units with hydraulic or electric motors and brakes.